Crankshaft Dowel Pin 'C' Engine

- Mark Sabbann

- 356 Fan

- Posts: 792

- Joined: Wed Mar 26, 2008 8:21 am

- Location: Stillwater, MN

Crankshaft Dowel Pin 'C' Engine

In the process of removing my flywheel to address a seal leak (the Torque Dude worked great: viewtopic.php?f=1&t=44287), I discovered one dowel pin was sheared off/broken with about 8mm coming off with the flywheel and the rest remaining in the hole in the crankshaft, recessed a few mm. What is the recommended way to remove the remains of the pin? My first attempt at drilling a pilot hole for an easy-out to be able to grab the pin was fruitless - they are very hard pins, as they should be. Ideas?

Mark Sabbann

1964 SC Coupe 'Essy'

1965 C Coupe 'The Yellow Delicious'

1964 SC Coupe 'Essy'

1965 C Coupe 'The Yellow Delicious'

- Don Gale

- 356 Fan

- Posts: 1181

- Joined: Wed Jul 26, 2017 6:27 pm

- Tag: Black A's Matter

- Location: Albuquerque

- Contact:

Re: Crankshaft Dowel Pin 'C' Engine

The dowel pins are hard, but not too hard to drill. Get a cobalt drill, not too small, and use more pressure. Hopefully the hole is well centered. When an easy-out bites, it will expand the dowel diameter slightly, making it tighter. A tap would be better. Once pilot drilled, use a larger diameter drill for the appropriate tap drill size. Use a tap drill size chart for 60-65 percent threads (slightly oversize drill size vs. std. tap drill size). The larger the tap drill size, the easier it will tap. Use a plug tap 1/2 turn in, 1/4 turn back and remove periodically to clear chips. Follow with a bottom tap. Once tapped, insert a screw as tight as you can get it and use a slide hammer to pop it out. In lieu of a slide hammer, you could drive it out with an appropriate height stack of washers under the screw head, remove the screw and remove 1 or 2 washers when it starts pulling out and repeat. If all of the above goes to crap, then live with 7 dowels and avoid doing burnouts and 2nd gear scratch and wait until the next rebuild and let a machine shop EDM the broken dowel out.

1958 356A 1600 Super Sunroof Coupe

former 1966 Euro 912 Sunroof

former 1978 Intermeccanica Speedster w/'68 912

Member Since 1983, #4039

"Nostalgia isn't what it used to be"

former 1966 Euro 912 Sunroof

former 1978 Intermeccanica Speedster w/'68 912

Member Since 1983, #4039

"Nostalgia isn't what it used to be"

- Martin Benade

- 356 Fan

- Posts: 12353

- Joined: Wed Nov 23, 2011 10:52 am

- Location: Cleveland, Ohio

Re: Crankshaft Dowel Pin 'C' Engine

It’s rather unusual for a single pin to crack, isn’t it?

Cleveland Ohio

62 Cabriolet

56 VW

02 IS 300

04 Sienna

62 Cabriolet

56 VW

02 IS 300

04 Sienna

- Don Gale

- 356 Fan

- Posts: 1181

- Joined: Wed Jul 26, 2017 6:27 pm

- Tag: Black A's Matter

- Location: Albuquerque

- Contact:

Re: Crankshaft Dowel Pin 'C' Engine

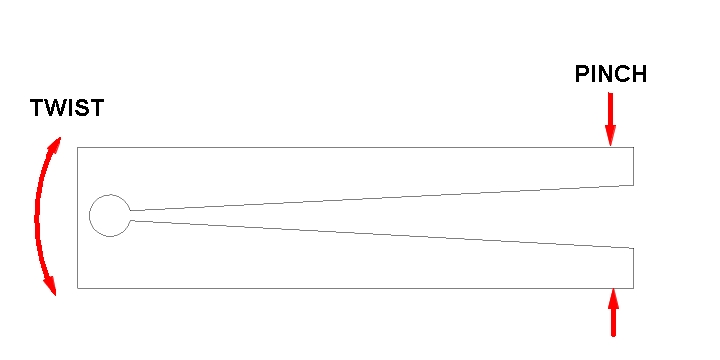

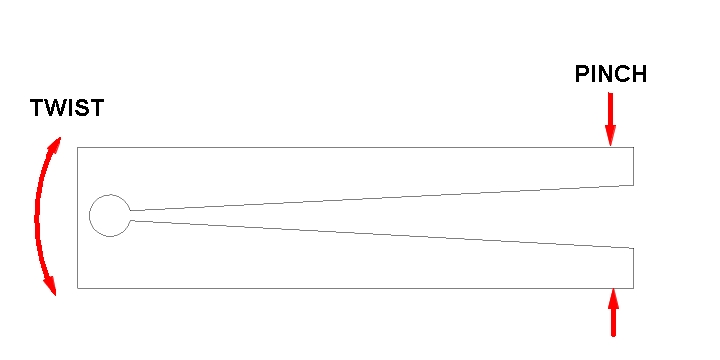

Very good observation. Best to remove all of them and replace with new. Here's a simple collet for gripping snug dowel pins. Use a scrap piece of 3/16" or 1/4" aluminum plate approx. 1" x 3" or 4" lg. Drill a hole the same diameter as the dowel (snug is better). Saw a vee shaped notch from the end to the hole. Slip the hole over the dowel, spread if necessary. Pinch the ends either by hand or with pliers and twist the dowels out.Martin Benade wrote: ↑Wed Sep 04, 2019 1:31 pm It’s rather unusual for a single pin to crack, isn’t it?

1958 356A 1600 Super Sunroof Coupe

former 1966 Euro 912 Sunroof

former 1978 Intermeccanica Speedster w/'68 912

Member Since 1983, #4039

"Nostalgia isn't what it used to be"

former 1966 Euro 912 Sunroof

former 1978 Intermeccanica Speedster w/'68 912

Member Since 1983, #4039

"Nostalgia isn't what it used to be"

-

Brad Ripley

- 356 Fan

- Posts: 4205

- Joined: Tue Mar 25, 2008 9:28 pm

Re: Crankshaft Dowel Pin 'C' Engine

Mark, Have you carefully inspected the overall condition of your crank? Determine condition before dealing with the dowel pin problem. Suggest not going any further. Just send the crank off to Walt at Competition Engineering http://www.competitioneng.com/CrankshaftRods.htm for a complete evaluation and possible repair. Also I believe Ollie's can do the same thing, see: http://www.olliesmachine.com/

- Martin Benade

- 356 Fan

- Posts: 12353

- Joined: Wed Nov 23, 2011 10:52 am

- Location: Cleveland, Ohio

Re: Crankshaft Dowel Pin 'C' Engine

It does sound unlikely that a perfect crank could break a dowel pin.

Cleveland Ohio

62 Cabriolet

56 VW

02 IS 300

04 Sienna

62 Cabriolet

56 VW

02 IS 300

04 Sienna

- Mark Sabbann

- 356 Fan

- Posts: 792

- Joined: Wed Mar 26, 2008 8:21 am

- Location: Stillwater, MN

Re: Crankshaft Dowel Pin 'C' Engine

It did seem a bit odd that only one broke. The soft iron gasket was split at that dowel location and was somewhat chewed up. The gland nut removal was not a problem and all threads are good. I will be putting a new gland nut etc. back on. And I will check and replace all the pins. Thanks for the tool suggestion, I might have some stock to work with. But if I plan to replace pins, is there a need to preserve the old pins, i.e. not use a vise-grip?Don Gale wrote: ↑Wed Sep 04, 2019 3:00 pmVery good observation. Best to remove all of them and replace with new. Here's a simple collet for gripping snug dowel pins. Use a scrap piece of 3/16" or 1/4" aluminum plate approx. 1" x 3" or 4" lg. Drill a hole the same diameter as the dowel (snug is better). Saw a vee shaped notch from the end to the hole. Slip the hole over the dowel, spread if necessary. Pinch the ends either by hand or with pliers and twist the dowels out.Martin Benade wrote: ↑Wed Sep 04, 2019 1:31 pm It’s rather unusual for a single pin to crack, isn’t it?

I don't plan on a whole engine tear down. What about the crankshaft might cause this such that it should be inspected?

Mark Sabbann

1964 SC Coupe 'Essy'

1965 C Coupe 'The Yellow Delicious'

1964 SC Coupe 'Essy'

1965 C Coupe 'The Yellow Delicious'

- Martin Benade

- 356 Fan

- Posts: 12353

- Joined: Wed Nov 23, 2011 10:52 am

- Location: Cleveland, Ohio

Re: Crankshaft Dowel Pin 'C' Engine

Look for wobbly dowel pins and check that the flywheel has the correct slight angle where it seats. That’s important, although I couldn’t tell you how to check that.

Cleveland Ohio

62 Cabriolet

56 VW

02 IS 300

04 Sienna

62 Cabriolet

56 VW

02 IS 300

04 Sienna

- Don Gale

- 356 Fan

- Posts: 1181

- Joined: Wed Jul 26, 2017 6:27 pm

- Tag: Black A's Matter

- Location: Albuquerque

- Contact:

Re: Crankshaft Dowel Pin 'C' Engine

If you can get them out with vise grips, then great. No need to care if the get scarred if not re-using them. The collet tool grips 10x better if the vise grips slips.

1958 356A 1600 Super Sunroof Coupe

former 1966 Euro 912 Sunroof

former 1978 Intermeccanica Speedster w/'68 912

Member Since 1983, #4039

"Nostalgia isn't what it used to be"

former 1966 Euro 912 Sunroof

former 1978 Intermeccanica Speedster w/'68 912

Member Since 1983, #4039

"Nostalgia isn't what it used to be"

- Martin Benade

- 356 Fan

- Posts: 12353

- Joined: Wed Nov 23, 2011 10:52 am

- Location: Cleveland, Ohio

Re: Crankshaft Dowel Pin 'C' Engine

Mark, had you had previous flywheel problems with this engine?

Cleveland Ohio

62 Cabriolet

56 VW

02 IS 300

04 Sienna

62 Cabriolet

56 VW

02 IS 300

04 Sienna

- Mark Sabbann

- 356 Fan

- Posts: 792

- Joined: Wed Mar 26, 2008 8:21 am

- Location: Stillwater, MN

Re: Crankshaft Dowel Pin 'C' Engine

To my knowledge, no problems with the flywheel. Prior to my initial ownership, the engine was rebuilt and a big bore kit installed. A few years ago I had the car on a dyno and it was pushed hard but has otherwise performed well since. This is the first time I have tried to address a long-time weep of oil from that area of the engine so this dowel issue is a surprise. I think I am on the right track as the engine as it sits, continues to weep at the bottom of the seal. The car was out of my hands for about 4 years before I got it back this spring and I don't know how it was driven in that time.Martin Benade wrote: ↑Wed Sep 04, 2019 10:01 pm Mark, had you had previous flywheel problems with this engine?

Martin, the rest of the pins seem solid and not ovalized or distorted, but can you clarify further what you mean by the 'correct slight angle'?Martin Benade wrote: ↑Wed Sep 04, 2019 6:44 pm Look for wobbly dowel pins and check that the flywheel has the correct slight angle where it seats. That’s important, although I couldn’t tell you how to check that.

Mark Sabbann

1964 SC Coupe 'Essy'

1965 C Coupe 'The Yellow Delicious'

1964 SC Coupe 'Essy'

1965 C Coupe 'The Yellow Delicious'

- Martin Benade

- 356 Fan

- Posts: 12353

- Joined: Wed Nov 23, 2011 10:52 am

- Location: Cleveland, Ohio

Re: Crankshaft Dowel Pin 'C' Engine

Hopefully CJ can clarify this. The mating surface where the iron gasket goes has a slight angle so it is tightest at the outer diameter. It is only a couple of degrees so almost invisible.

Cleveland Ohio

62 Cabriolet

56 VW

02 IS 300

04 Sienna

62 Cabriolet

56 VW

02 IS 300

04 Sienna

- Ron LaDow

- 356 Fan

- Posts: 8092

- Joined: Wed Mar 26, 2008 11:45 am

- Location: San Francisco

Re: Crankshaft Dowel Pin 'C' Engine

Pretty sure that very few shops are going to be able to measure the part to confirm that angle. From memory, it's ~2* over the distance of < 1Cm, and you're looking at NIST-traceable instruments to confirm that. Or, yes, for the pedants here, you could take a some sort of a mold and use a optical comparator, and still need those NIST tools to make it "real".

You will be able to confirm the surface is so angled, and not damaged, with a straight edge, a back light and some sort of visual aide (wife calls them 'peeps', 5:1 or so, in my case); there will be a visual 'clearance' at the center and none at the periphery. Absent visible damage, it's likely to be good.

Last time I had a question, the machine shop didn't bother to measure it, they simply ground it to the proper angle, and left it to me to shim the F/W to the proper distance.

You will be able to confirm the surface is so angled, and not damaged, with a straight edge, a back light and some sort of visual aide (wife calls them 'peeps', 5:1 or so, in my case); there will be a visual 'clearance' at the center and none at the periphery. Absent visible damage, it's likely to be good.

Last time I had a question, the machine shop didn't bother to measure it, they simply ground it to the proper angle, and left it to me to shim the F/W to the proper distance.

Ron LaDow

www.precisionmatters.biz

www.precisionmatters.biz

- Juha Vane

- 356 Fan

- Posts: 312

- Joined: Tue Jul 01, 2008 3:06 pm

- Location: Sumiainen, Finland

Re: Crankshaft Dowel Pin 'C' Engine

Here from Spec Book the flywheel angle.

Recommend that you get this little book.

Recommend that you get this little book.

KTF,

Juha Vane

Finland

'59 308

'63 356

'85 911

Juha Vane

Finland

'59 308

'63 356

'85 911

- Harlan Halsey

- 356 Fan

- Posts: 2371

- Joined: Fri Mar 02, 2012 2:05 pm

- Location: No Cal SF Peninsula

Re: Crankshaft Dowel Pin 'C' Engine

It's pretty easy to measure that angle. From memory, I think it is about 1.5 degrees. Dean Lyon can re-machine that surface if necessary. I have a pair of flywheels, one 356 and one 912, on which I had him equalize that surface so that I can easily move my spare engine between cars without changing the flywheel shim.